(A) dance on the knife - stamping operations

Before a heavy punch, two workers are working. The left side of the operator will be heavy steel plate into the punch, began to lock the screw positioning, the whole body of the upper body in a piece of about 5 tons of steel mold. When the lock is locked, the right side of the worker presses the start button, and after the steel mold is stamping, a stamping part is taken out.

"My life is manipulated in his hands every day, he was a little nap, light my arms amputation, heavy I first explain it!" He said with a smile.

Stamping molding, modern metal processing in the most convenient and efficient savings of the molding process. Small to pots and pans large to the plane ships, stamping process everywhere. The use of high-strength mold in the huge momentum caused by the deformation of processing, the potential risk is self-evident. "Just like dancing on the tip of the knife," a worker said artfully.

(B) wind and on - four-axis swing arm punching manipulator

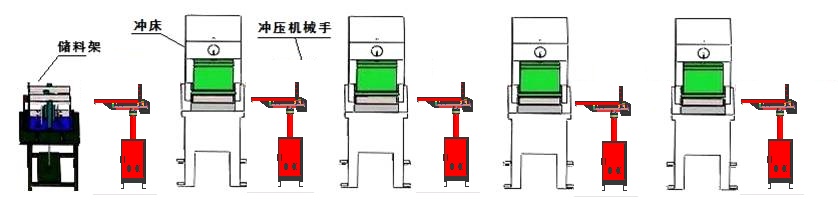

At the beginning of 2015, the design of 5 kg bearing four-axis swing arm punching machine just off the line, extension of the old customers to fight to order, many companies will be such a light stamping robot as a standard machine to promote the application. This kind of positioning precision, fast speed, simple operation, flexible assembly for single machine single machine, stand-alone multi-mode, multi-punch online production, can replace the artificial stamping station in the material stamping, handling, loading and unloading work, Can achieve a value of 6-10 machines.

Multi-faceted advantages for many small and medium enterprises feel excited, stable, standardized, continuous work, no doubt solve a lot of business people move difficult, tricky, difficult to keep the problem, and keep a machine with a person's costs will follow The more obvious the longer the gains.

(C) people-oriented - large, heavy stamping automation program

In the face of millions of orders, as the extension of the project engineer Dong Shougang and his team did not have much excitement, 5 kg load stamping parts only stamping process is a small part of the application, more like the beginning of the article described Large, heavy stamping projects require more advanced automation, higher power, more robust construction, higher strength materials, and more complex line conditions.

With the robot (300024) to replace the people to complete high-risk, repeat, high-intensity work, a simple words full of too much content. Stamping is the most typical work full of danger, the workers put the first is the technical staff should always be self-required criteria.

In 2016, Tuosida stamping team has designed a number of enterprises for the large-scale stamping equipment automation program, heavy-duty stamping automation program, a mature program design, professional sense of service, people-oriented program concept, so that extension of the stamping automation Industry quickly broke out.

(4) the heart of craftsmen - the combination of technology and people

When more peers will be technical barriers, product profits as difficult to overcome, the extension of the stamping team continue to strengthen the customer-centric, technology people-oriented design concept how to do people-oriented team said. The

1: a more secure design.

Safety is not only reflected in the visible equipment on the human body hazards, more potential harm. The potential danger in the life of the machine must be taken seriously at the beginning of the design and the hidden danger should be eliminated.

2: a more simple mode of operation.

Enterprises to develop an automation operator need to match a lot of resources, and the use of a more simple touch screen and system design, will be easier for practitioners to get started with automated applications.

3: more flexible technology applications.

Visual system, information detection, force sensing, from automation to intelligent is the inevitable trend of technological progress, but all around the development of people-centered.

The In the face of market demand, people-oriented is the prerequisite for the existence of each business body will be combined with the concept of technology and humanities, Tuosi stamping automation is practicing the concept of brand extension: let the industrial civilization return to the beauty of nature.