In order to meet the flexible production requirements, all the control functions of the press should be integrated to achieve a full set of mold menu management, including slider stroke adjustment, balancer pressure adjustment, air cushion stroke adjustment and automation control system Parameters are set for each link. Fieldbus technology with field communication network, field device interconnection, interactive operation, decentralized function module and open function is the development direction of press control technology, and it has obvious impetus to realize automation. Integration of the control system The control functions of all press and molds can be realized through a single operating interface, including fault diagnosis, mold menu configuration, programmable limit switch and mold monitoring and adjustment, and make the equipment more convenient for maintenance , And significantly increase the effective working hours of the press.

Stamping robot servo drive system is the most prominent feature: the motor directly with the eccentric crank gear interconnected, because the motor speed can be adjusted, so you can arbitrarily adjust the crank mechanism of the movement speed, any speed up or slow down the servo press. Another major feature is the high compatibility. As the servo press the motor speed can be stepless adjustment, it is possible in the stamping process to achieve stamping and punching force of the stepless adjustment, so that the press working curve with a variety of different application requirements to match. In order to ensure that the crank to complete the precise movement, the user can achieve through the deceleration of the drawing process or to maintain a constant stamping speed, which can not only improve the quality of sheet metal processing, but also extend the use of molds Servo press speed changes and control Reasonable optimization design, and the use of integrated modules, in accordance with the modular structure of manufacturing, if you do not need to use its servo function, the machine can work like a traditional press, to maintain a constant power and travel.

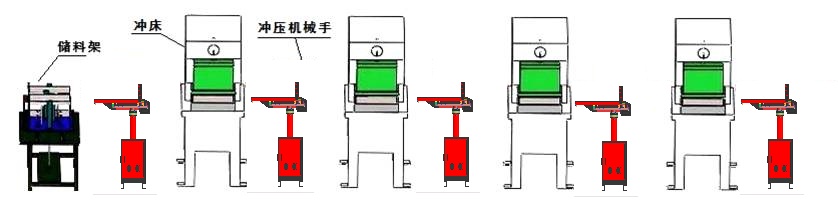

Stamping manipulator is widely used in household appliances, automobiles, packaging, cosmetics, electronics and other industries to produce hard plastic, with the punch machine to remove the product, for enterprises to save labor, before a machine in the absence of mechanical conditions to match one or two Workers, after using the manipulator, basically can be a worker at the same time operating 3-10 sets of machine tools, Borisi professional R & D and production of various punch robot, for single machine single, single multi-mode, multi-punch online production And so on, the robot can be up and down, left and right movement, while 360-degree rotation axis, fully adapt to a variety of stamping automated production process requirements.